SPONSORFoundations in Personal Finance High School Curriculum

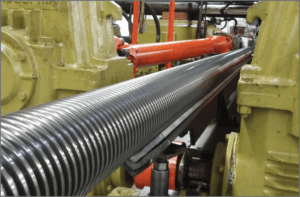

Our thread rolling machines use a constant hydraulic force at high pressures to ensure the form of any thread we make is fully realized. This cold-working process not only saves cost by eliminating material waste compared to cut threads, but also creates a smooth, work-hardened exterior which makes them stronger and longer-lasting.

We provide a wide variety of industries with quality standard and customized threaded rods and machined products, including:

No matter the application, Keystone Threaded Products is recognized for excellence in manufacturing products for strength, quality, and dependability. If your industry isn’t listed, we are confident we can meet your threaded rod needs.

We manufacture precision roll threaded products, specializing in Acme, trapezoidal, and unified form threads as well as large diameter threading. We make an assortment of hex, round, and cylindrical nuts to mate with our threaded rod as well as special screws and nuts to meet our customer needs.

Our materials include carbon steel, alloy steel, stainless steel (303, 304, 316), brass, bronze, aluminum, and exotic metals.

We manufacture standard and customized precision threaded rod products for a broad range of industries. From fully threaded bar and double end studs to bolts, lead screws, and specialty fasteners, we are recognized for excellence in manufacturing products for strength, quality, and dependability.

We stock a variety of threaded rod and other products, including 3/8″ to 2″ diameter threaded stainless steel, B7 and low carbon rod; ACME, national course, and national fine thread patterns; a variety of thread pitches; and 12′, 6′ and 3′ bar lengths (or cut to size). Contact us directly for questions about sizes, finishes, inventory or pricing.

We have secondary machining capabilities in house as well as a network of strategic partners fully vetted by our production team. Our capabilities include:

CNC Turning Capacity

Specialty Turing Capacity

Other Capabilities

Yes. See answer to previous FAQ: Does Keystone Provide Parts Complete?

Yes. All of our products are 100% U.S. sourced and manufactured.

The “Made in the USA” label indicates that all significant parts of a product are produced, manufactured, and assembled in the US. This label is regulated by the Federal Trade Commission.

We offer national course, fine, and Acme threads as aggressive as 1.5 pitch in addition to metric and trapezoidal threads. Threads can be right or left hand. Additionally, our CNC department can machine bar ends to your specifications. We make an assortment of hex, round, and cylindrical nuts to mate with our threaded rod as well as special screws and nuts to meet our customer needs.

Keystone is an officially certified Women-Owned Small Business (WOSB) through the U.S. Small Business Administration, making us eligible to participate in the WOSB Federal Contract Program.

Simply Contact Us. The time we need to review a quote depends on the complexity of the request. Most quotes will be provided within 24 to 48 hours. Quotes for complex custom items may take longer.

We are ISO 9001 certified and are committed to consistently providing quality roll threaded products. We thoroughly test our products by performing in-process testing and inspection.

Keyalloy is the trademarked name that Keystone uses for our alloy heat treated roll threaded bars. Keyalloy is a 4140 alloy steel heat treated to the requirements of ASTM A193 / ASME SA 193 Grade B7, latest revision.

Hot dip galvanized bars are only available in products up to three feet in length. We do not stock any bars that are hot dip galvanized; therefore, a minimum plating charge would incur on all special orders.

A machined chamfer is a mechanically created chamfer produced by means of a secondary operation. A 30° axial (60° included angle) measured below the minor diameter of the bar is produced. A rolled chamfer is created during the process of roll threading bars. It results in a good starting thread, but creates no measurable angle.

A machined chamfer is a mechanically created chamfer produced by means of a secondary operation. A 30° axial (60° included angle) measured below the minor diameter of the bar is produced. A rolled chamfer is created during the process of roll threading bars. It results in a good starting thread, but creates no measurable angle.